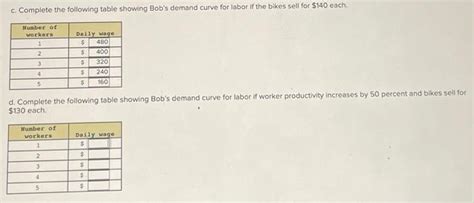

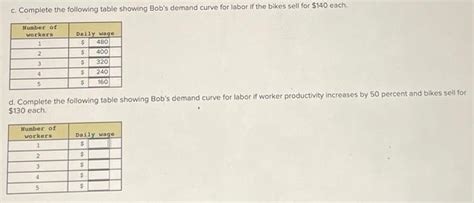

production data for bobs bicycle factory are as follows: ,Solved Production data for Bob's Bicycle Factory are ,production data for bobs bicycle factory are as follows:,Instructions: Enter your responses as integer values. a. Bikes sell for $130 each. Find the marginal product and the value of the marginal product for each worker. Don’t forget to consider Bob’s cost for parts. b. Complete the following table showing Bob’s demand curve for labor. The 2015 release of the Cartier Crash Skeleton was a significant moment in the story of the Cartier Crash. The design incorporated a skeletonized dial, which revealed the inner mechanics of the watch. Available in materials such as pink gold and platinum, this model retained the iconic asymmetrical case but gave enthusiasts a peek inside the .

Bob's Bicycle Factory is a small business that specializes in producing high-quality bicycles. Bob, the owner, constantly monitors the production data to ensure efficiency and profitability. The production data for Bob's Bicycle Factory are as follows:

Number of Workers: Bikes Assembled per Day

1: 10

2: 18

3: 24

4: 28

5: 30

In addition to wages, Bob incurs costs of $100 for parts and other materials for each bike assembled. Analyzing this production data is crucial for Bob to make informed decisions to optimize his production process and maximize profits.

The relationship between the number of workers and the bikes assembled per day is evident from the data. As the number of workers increases, the production output also increases. This relationship is essential for Bob to determine the optimal number of workers needed to achieve the desired production level efficiently.

By analyzing the production data, Bob can calculate the labor productivity of each worker. Labor productivity is a critical metric that assesses the efficiency of the workforce in producing goods. It is calculated by dividing the total output (number of bikes assembled) by the total input (number of workers). By analyzing the labor productivity, Bob can identify any inefficiencies in the production process and take corrective actions to improve productivity.

Furthermore, the cost analysis is essential for Bob to understand the total cost of production per bike. In addition to the labor costs, Bob incurs a fixed cost of $100 for parts and materials for each bike assembled. By calculating the total cost per bike, Bob can determine the profitability of each unit produced. This information is crucial for setting the selling price of the bicycles to ensure that the business remains profitable.

Moreover, Bob can conduct a break-even analysis using the production data. Break-even analysis helps Bob determine the level of production at which the total revenue equals the total cost, resulting in neither profit nor loss. By identifying the break-even point, Bob can make informed decisions on production levels, pricing strategies, and cost control measures to ensure the financial sustainability of the business.

production data for bobs bicycle factory are as follows: $10K+

production data for bobs bicycle factory are as follows: - Solved Production data for Bob's Bicycle Factory are